About a month and a half ago, I broke a HED Big Deal rim. It was the rear wheel and it broke while I was riding on rocky terrain on the East Coast of the USA. I had about 8 hours of riding on the wheel in total, which was shod with a tube and a Maxxis Mammoth 4″ tyre at 9psi. For the record, I weigh 88kg and I don’t believe I am a clumsy rider.

Whilst descending a sweet singletrack, near Frederick’s Watershed, on rocky but not sharp edged terrain – think smooth, rounded rock – a loud crack announced a rim break. The rim edge basically frayed apart for 2.5-3cm circumferentially and there was a crack into the flat area of the rim, around 1cm. The tyre wasn’t punctured and I would admit I felt it was pretty bad luck as I was still feeling my way to full speed on the bike (which was new) and had not anticipated any particular risk. There is no real doubt in my mind this was caused by a rim strike.

To add some background to my experience – I have ridden extensively on 3 other brands and 5 sets of carbon rims on terrain accross europe and the USA for many years. I have had more rim strikes than I can count due to punctures or just hard impacts. I have had one rim delaminate, in a very minor way, which was replaced by the company in a responsible and timely fashion. I have had no significant rim damage from riding. All the rims in question have marks, scratches and signs of a happy and good life, but that is all.

On building the HED wheels (being from the UK, HED Big Deal rims are available separately, unbuilt, whereas in the USA they are only available built by HED) I was mesmerised not just by the lack of heft, but the unimaginably thin rim bead seat edge. In truth, I was half expecting the rims not to hold up to all trail conditions.

So – why was I riding rocky trail if I was potentially expecting a rim break? Well, HED’s assurances* that the rims were up to it was part and also I would add that I have spent years assessing bike parts not just for my own use but at times for public consumption through UK bike publications. I needed to see if these rims would hold up to back country scottish riding – the purpose of the bike they were mounted to.

The answer? no.

At the time, I was fairly sanguine about the break. I figured that given the previous assurances, publicly* and to several good and astute friends (including Sean at Vertigo Cycles), I would probably be able to replace the rim with a crash replacement – admitedly at what I believe to be 75% of cost – but at least I would then know the rims were only suitable for me on snow or buff trail in the future.

Well, it has been over a month now after HED have been contacted, repeatedly, sent pictures for assessment and I have had no response.

Personally, I find that unaceptable, regardless of the performance of the rim.

I am aware there are others – including riders I know in the UK – who have had no issues with the rims. That’s fine. For me, they would not inspire confidence in any situation where I was fully relying on them to get me home and the trail was even moderately rocky. Perhaps with wider tyres, >4″ so the edge was more protected? or perhaps with higher pressure this would not be the case, but then this requires stipulation by the company to allow the user to decide if they are buying the right product. There is always going to be a market for the lightest stuff, even if conditions of use are limited.

It is the lack of communication I find so disappointing.

So, I can count myself lucky that I can chalk this up to experience. I have repaired some carbon fibre parts in the past and will do so with this rim and continue to use it at times, out of curiosity, but I will also build another brand of carbon rim into a wheel for use where I believe the HED rim is not up to the job.

Of course, perhaps I have a rim that had a manufacturing defect – this happens, occasionally – but if HED are not interested then we will never know.

If you are looking at a set of HED Big Deal or BFD rims, I would self assess very clearly before buying them. They are expensive and may not hold up to general riding as advertised. If they dont, you may find yourself, like me, ignored.

A couple of last points:

As mentioned in the building post, I bought these rims from Sideways Cycles in Alsager. Tim is a good friend as well as one of the people whose knowledge and experience in the bike world I respect the most. He has tried untiringly to engage HED. I can only thank him for all the effort, above and beyond.

Sean broke his rear HED rim on the same ride, in the same way.

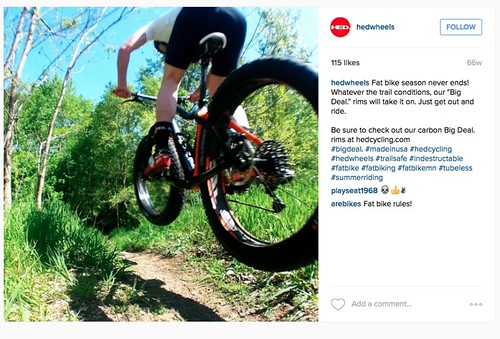

*at a couple of points I mention the fact HED publicly okayed the use of Big Deal rims in an unrestricted fashion. There was nothing equivocal about this. This is a post from HED’s instagram account.

Although it has proven reasonable to be skeptical, it remains the lack of communication that I find the most disappointing aspect.